WOP | Workshop of Photonics, one of the leading femtosecond laser micromachining solutions providers for industry & science customers around the globe, expands its portfolio, offering a guaranteed precision solution for optical communication systems.

The solution enables reaching excellent precision results in optical fiber alignment array fabrication – the crucial component in optical communication systems – resulting in low-loss, high-speed, large-capacity communication.

“We continuously make investments and strive to be in front of micron-scale challenges to meet evolving customer needs. Our core is an innovative approach to laser technology, continually researching and developing new technologies, techniques, and applications,” said Dr. Gintautas Šlekys, Founder & CEO at WOP | Workshop of Photonics.

High-speed optical communications drive the demand for fiber alignment structures

The demand for fiber alignment structures has been growing in recent years, driven by the increasing demand for high-speed and reliable optical communications systems.

The growth of data-intensive applications, such as cloud computing, big data, and the Internet of Things (IoT), has led to an increase in demand for fiber-optic networks, which has, in turn, driven the demand for fiber alignment structures.

The most common application of optical fiber alignment structures includes optical communication systems to transmit data over long distances with high bandwidth and low latency.

Optical fiber alignment arrays require precise alignment and positioning – the micro-holes formed in the optical fiber alignment array must be uniformly aligned and in a uniform pitch. The precision optical fiber alignment structures ensure that optical fibers are aligned accurately, providing reliable and consistent transfer of light and data.

Laser technology for ultra-fast communication

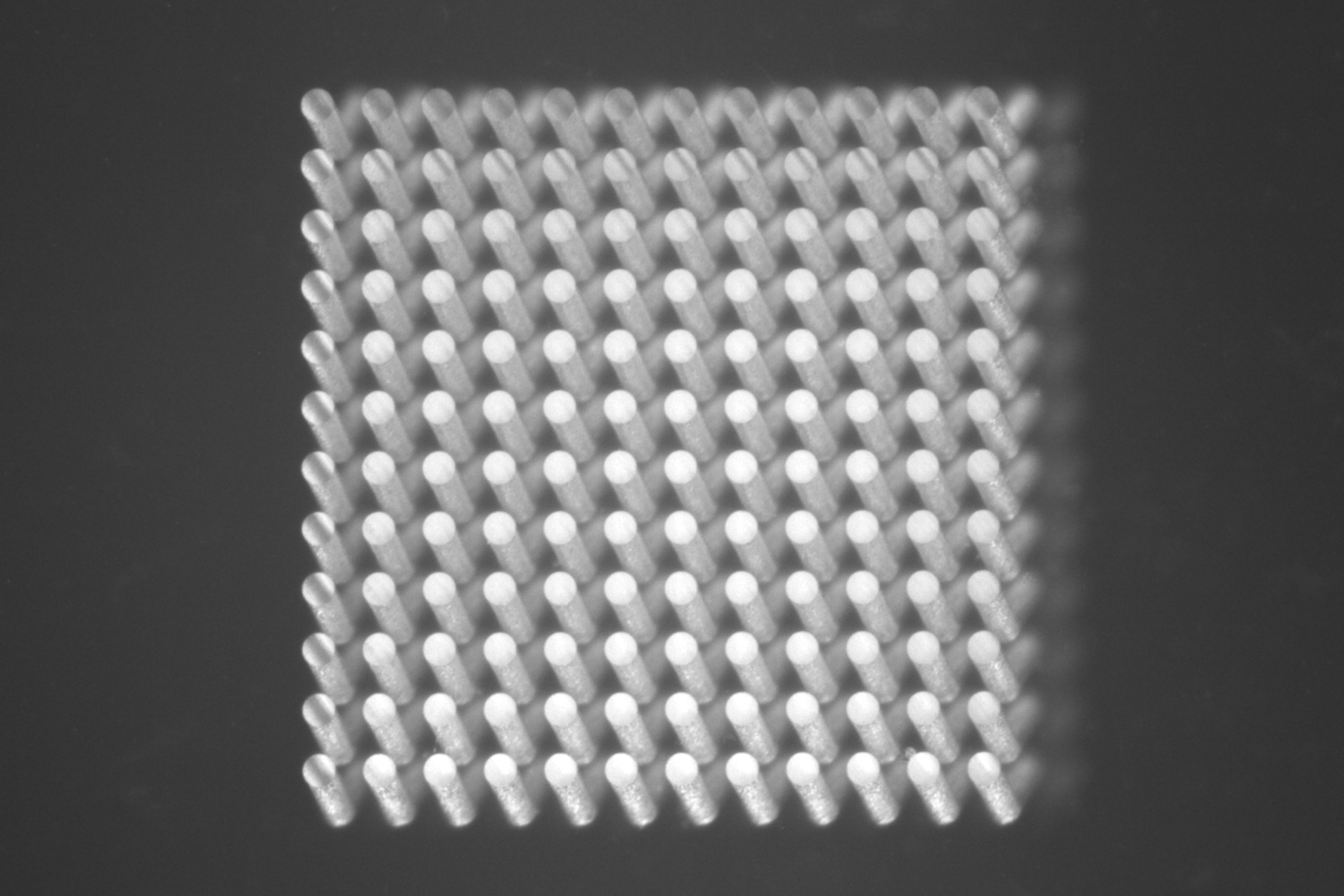

While there are one-dimensional and two-dimensional (2D) arrays, the need for speed and growing data quantities increases demand for 2D arrays of optical fibers. They are versatile and flexible components used in diverse applications that require precise optical fiber alignment and positioning.

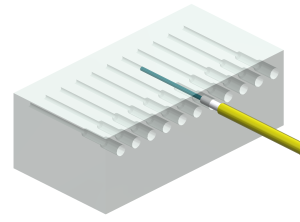

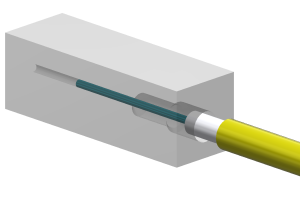

One row of fiber arrays with SMF fiber

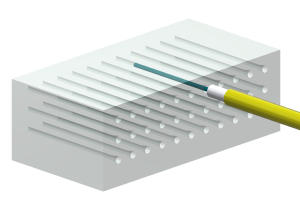

Example of fiber arrays with SMF fiber

2D fiber arrays with SMF fiber

However, the production process of 2D optical fibers arrays is more complex vs. 1D, and while 2D arrays can be fabricated using diverse techniques, femtosecond laser micromachining, together with selective laser-induced etching (SLE), demonstrates definite advantages in precision, consistency, speed, material versatility, and cost-effectiveness.

Using this laser micromachining method, critical features such as tight tolerances, tight positional accuracies, and hole diameter – within the tolerance of ±0.25 μm – can be achieved. This tight control of metrics ensures well-controlled alignment that might reduce insertion loss and provide good repeatability.

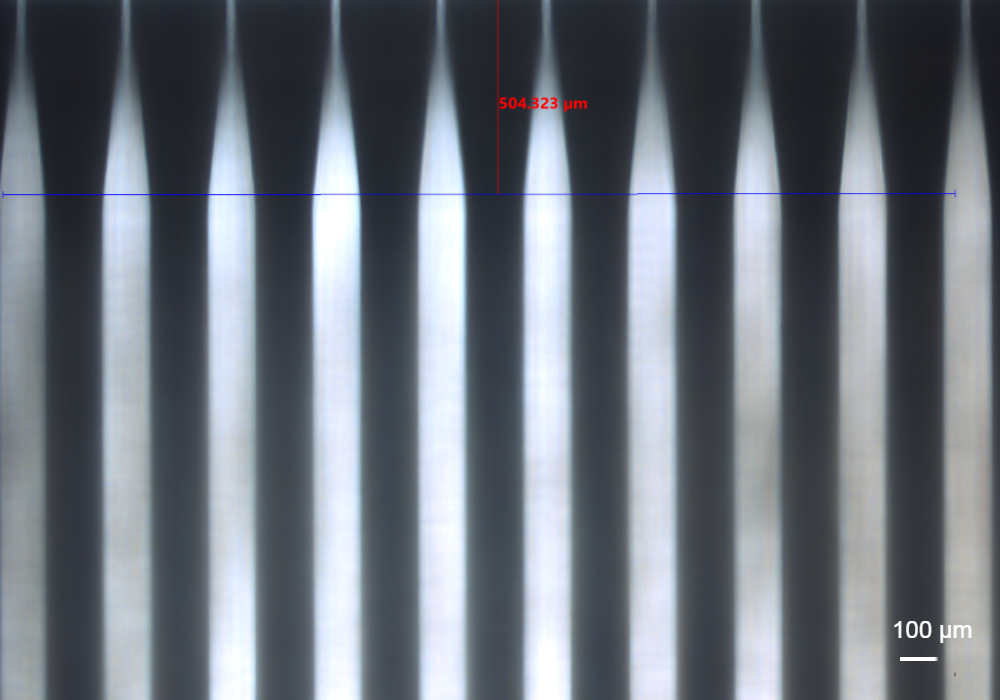

Moreover, this method enables forming the hole entrance as a funnel, step profile, or with a conical taper for easy fiber insertion. The channels can be straight or angled (like 8̊ ). The picture shows examples of hole entrances and possible angles.

Even though it is designed for standard SMF fibers with a diameter of 125/250 µm, the laser micromachining with the SLE method is not limited to it – other diameters are also available (80 μm or less).

The other definite advantage is ultrafast direct laser writing speed, making this method suitable for high-scale production (WOP capacity is up to 10,000 precision fiber alignment units per month per laser machine).

_______

Read full press release here Contact us to learn moreThe results, achieved using FemtoFBG present the stabilization of blue multi-emitter modules using fiber Bragg…

This EU-funded project is expected to revolutionize Green Energy Generation from photovoltaic panels across Europe.

WOP participates in the BILASURF project – a new European initiative to develop a solution…