Thermal effects in a high-power laser’s gain medium create predictable axially symmetric temperature gradients. Temperature gradients generate mechanical stresses in pumped crystal, which lead to induced birefringence.

Generated optical anisotropy causes significant power losses if a laser system contains polarization-sensitive elements (eg Brewster plates, Faraday rotators).

Workshop of Photonics | WOP, in a joint effort with Ekspla Ltd., based on Ekspla Ltd invention EP3712664 (A1), developed and verified a solution to solve the depolarization loss issue – an optical element that compensates distortion of original polarization in the gain medium.

A subpicosecond laser system was investigated, featuring fiber CPA-based seed laser FemtoLux 30 (Ekspla) and a double-pass end-pumped Yb:YAG crystal power amplifier [1].

The key novelty of the system was the application of depolarization compensation using a specially designed spatially variable wave plate or SVWP, which allowed the extraction of nearly maximum power from such an amplifier without additional beam quality degradation.

To the best of our knowledge, this method has been applied for the first time [1].

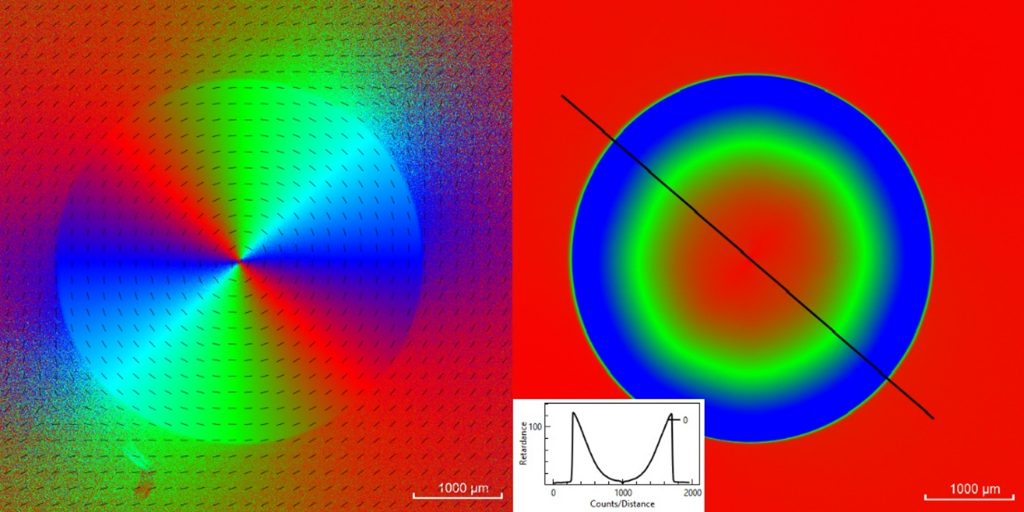

Depolarization compensator. Left: Two-dimensional distribution map of the orientation of fast and slow axes. Right: Retardance profile.

Our proposed depolarization compensation method – a depolarization compensator – is more beneficial compared to other methods, such as intracavity quarter-wave plate, intracavity Faraday rotator, classical depolarization compensation layout with two identically pumped and relay-imaged gain media, and different crystal cut directions.

WORKSHOP OF PHOTONICS

Mokslininku st. 6A, Vilnius, LT-08412, Lithuania

Phone: +370 5 215 7551

E-mail: [email protected]

Altechna R&D, UAB

Company code 301502628

VAT code LT100006155012

Bank – SEB 70440

LT87 7044 0600 0770 8092