Higher-order S-waveplate converts linear polarization to higher-order polarization patterns.

The fabrication of s-waveplates is based on the inscription of self-organized nanograting’s inside fused silica glass using a femtosecond laser.

LIDT measurements at fs regime (full report) and ns regime (full report) show our S-waveplates have laser irradiation resistance similar to uncoated fused silica substrates. LIDT value measured at 1064 nm, ~10 ns is 63,4 J/cm² and it is not dropping while increasing exposure time. It proves, our waveplates are very high performance and suitable for high power laser applications.

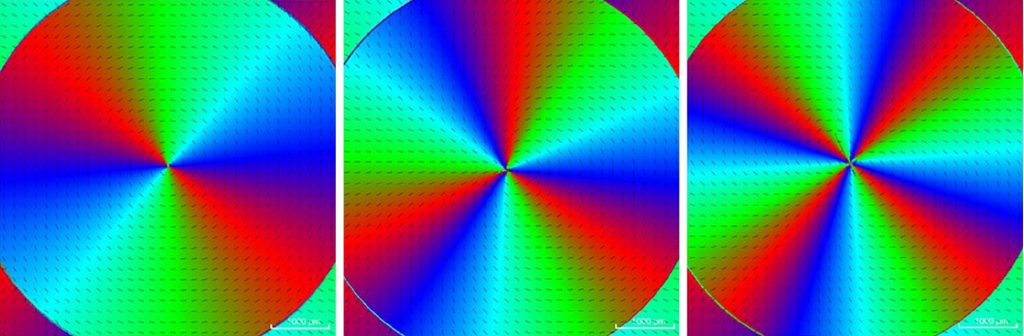

Examples of fast axis patterns for 2nd (left), 3rd (center), and 4th (right) order S-Waveplates (measured with Hinds Instruments Exicor MicroImager).

WORKSHOP OF PHOTONICS

Mokslininku st. 6A, Vilnius, LT-08412, Lithuania

Phone: +370 5 215 7551

E-mail: [email protected]

Altechna R&D, UAB

Company code 301502628

VAT code LT100006155012

Bank – SEB 70440

LT87 7044 0600 0770 8092