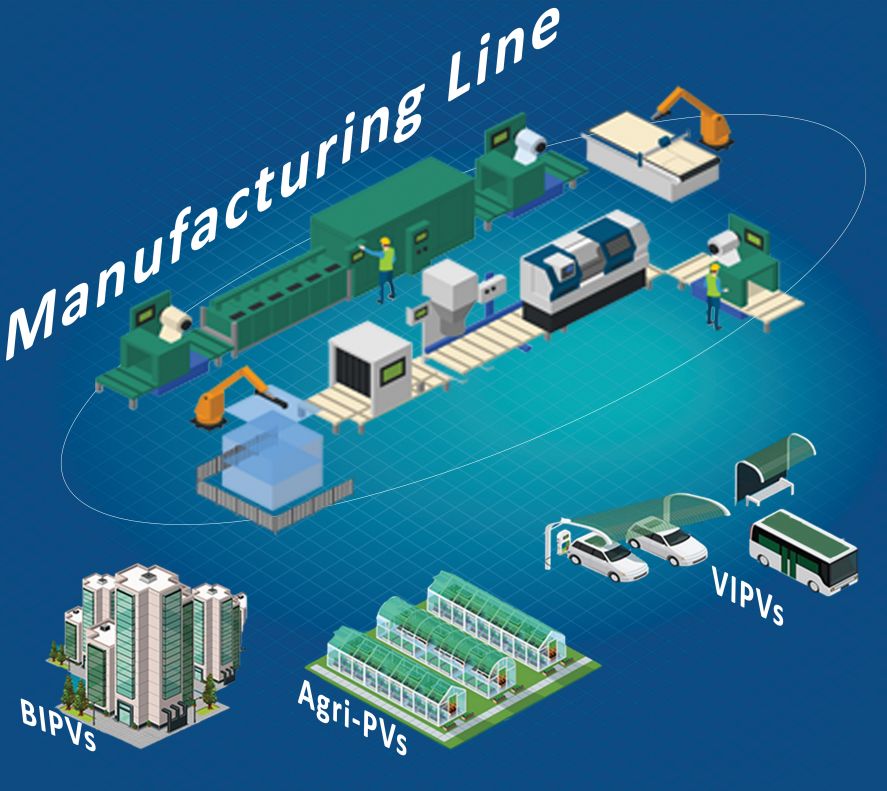

WOP participates in the EU-funded Flex2Energy project with an ambitious goal of manufacturing reliable Integrated Photovoltaics (IPVs) Products by developing an Automated R2R (Roll-to-Roll) Manufacturing Line for Organic PVs (OPVs).

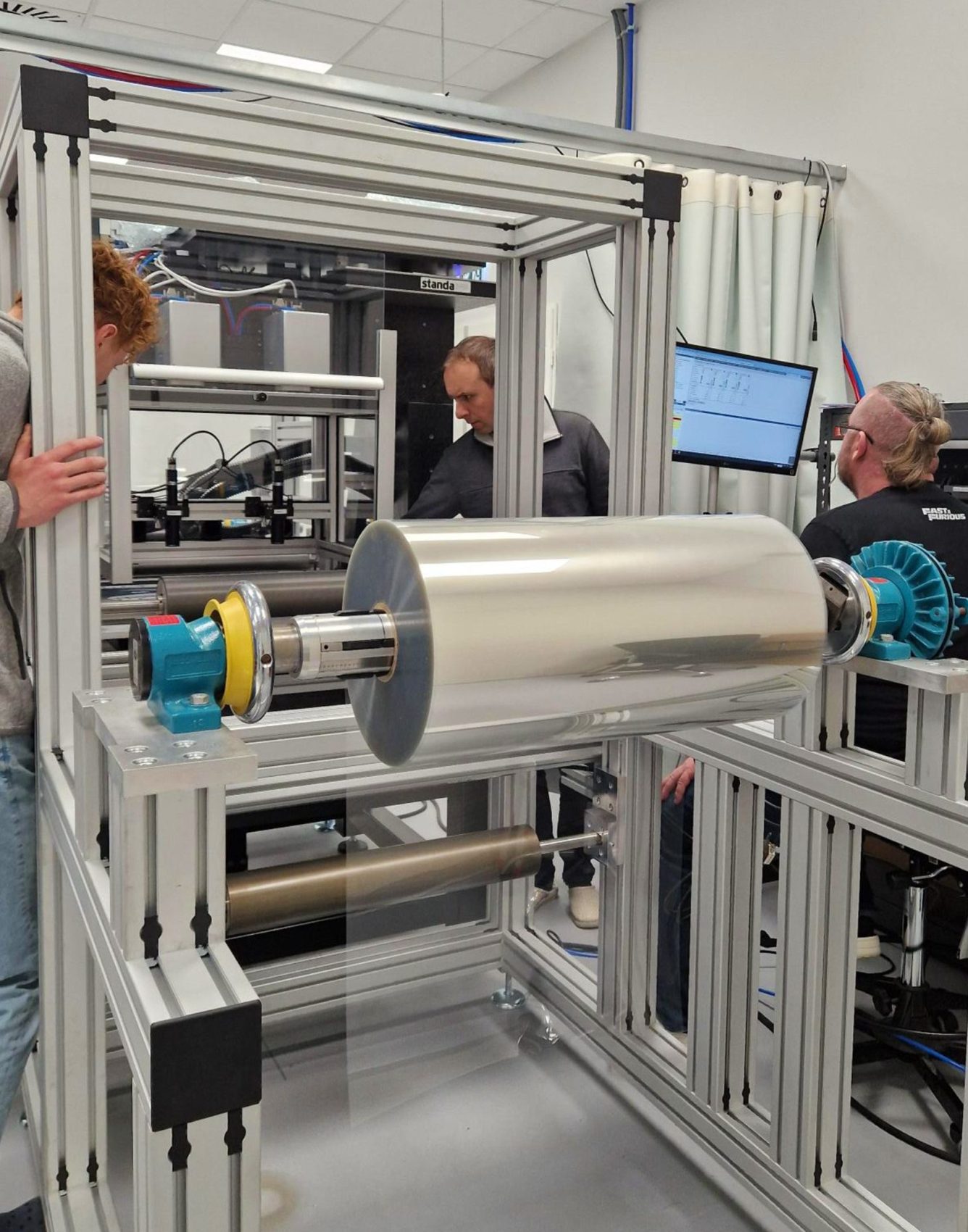

The Manufacturing Line consists of R2R Printing & Automated Assembly Machines, with robust and adaptive in-line metrologies for quality control and Artificial Intelligence (AI) analysis implementing industry 4.0 concepts.

The IPVs will be produced in custom designs complying with the requirements of use in buildings, greenhouses for energy production & crop harvesting, and automotive EV car roofs, to minimize landscape and facilitate energy-positive buildings.

The IPV products will be installed in dedicated business cases (BIPVs, Agri-PVs, VIPVs) and will be evaluated in terms of performance, durability, and social and industrial acceptance.

This project is expected to revolutionize Green Energy Generation from photovoltaic panels across Europe. It will create a mass production plant for organic photovoltaics, making the European Union independent from imports.

F2E will implement innovative IPV products in three dedicated business cases to promote their early adoption and boost the new market demands.

BIPV products will be installed on public and heavy industry building façade as energy efficient windows, while Agri-PVs will be installed on the roof of a Med GH working as a shade curtain system for the growth of tomatoes and as an energy generator making the GH energy autonomous.

Finally, VIPVs will be installed on the roof of a commercial EV to increase mileage and also on the roof of a solar Carport to provide energy to electric vehicles. The IPV products will be evaluated in terms of performance, durability, and social and industrial acceptance.

The results, achieved using FemtoFBG present the stabilization of blue multi-emitter modules using fiber Bragg…

WOP participates in the BILASURF project – a new European initiative to develop a solution…

Visit us at the upcoming exhibitions in the USA: SPIE Photonics West, MD&M, and OFC…