Bilasurf – new methods for surface functionalization of complex 3D parts using a laser-based high-rate process

WOP participates in the BILASURF project – a new European initiative to develop a solution for surface functionalization, which aims to reduce friction and improve the environmental footprint of industrial parts.

The project unites a multinational team from 10 organizations with diverse backgrounds.

WOP tasks in the project comprise precise positioning of the complex 3D-shaped workpieces according to a predefined algorithm and integrating all components and modules provided by other consortium members into a machine suited for texturing the Demonstrators of the project, Francis turbine by Global Hydro, and mold for impeller blades by Ziehl-Abegg.

Surface functionalization is present in diverse sectors, improving the performance of multiple components and systems in many applications. However, such functionalization application in complex industrial parts faces some difficulties, especially when reaching all surfaces of complex 3D parts is significant and with considerable size and weight.

Traditional surface functionalization methods that rely on processes such as chemical reactions and the complete coating of the native surfaces generate unwanted by-products, leaving a significant environmental footprint.

To avoid these setbacks, a new functionalizing process for complex 3D-shaped parts in which the environmental footprint is reduced, and new guidelines generated to complement the manufacturing standards of target sectors could be a game changer.

The new process is based on laser technologies for surface functionalization, providing a green, flexible, and digital way to produce goods.

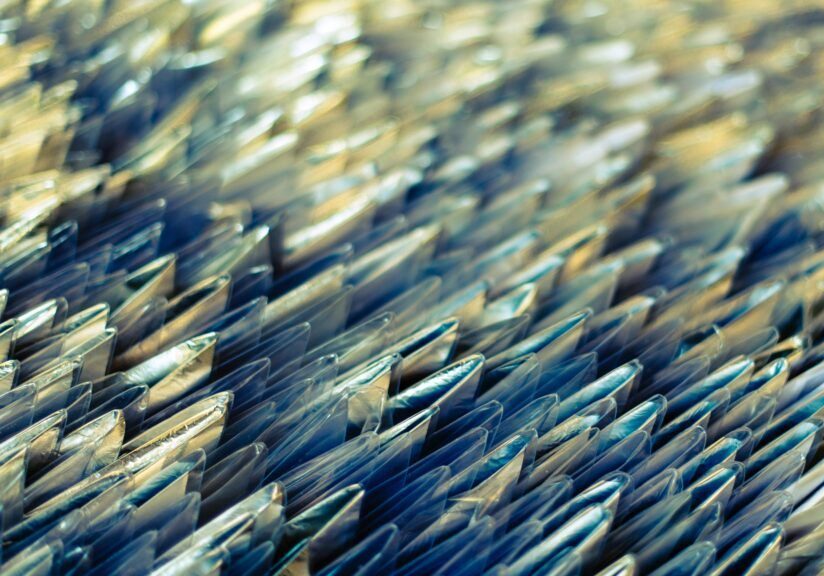

Laser structuring is a highly appealing alternative for producing tailor-made riblets with a continuously variating cross-section.

An additional advantage of laser structuring is its versatility, which enables it to tackle the generation of a wide variety of nano- and microstructures on a wide range of parts of different sizes and shapes.

More about the Bilasurf project: www.bilasurf.com

The results, achieved using FemtoFBG present the stabilization of blue multi-emitter modules using fiber Bragg…

This EU-funded project is expected to revolutionize Green Energy Generation from photovoltaic panels across Europe.

Visit us at the upcoming exhibitions in the USA: SPIE Photonics West, MD&M, and OFC…