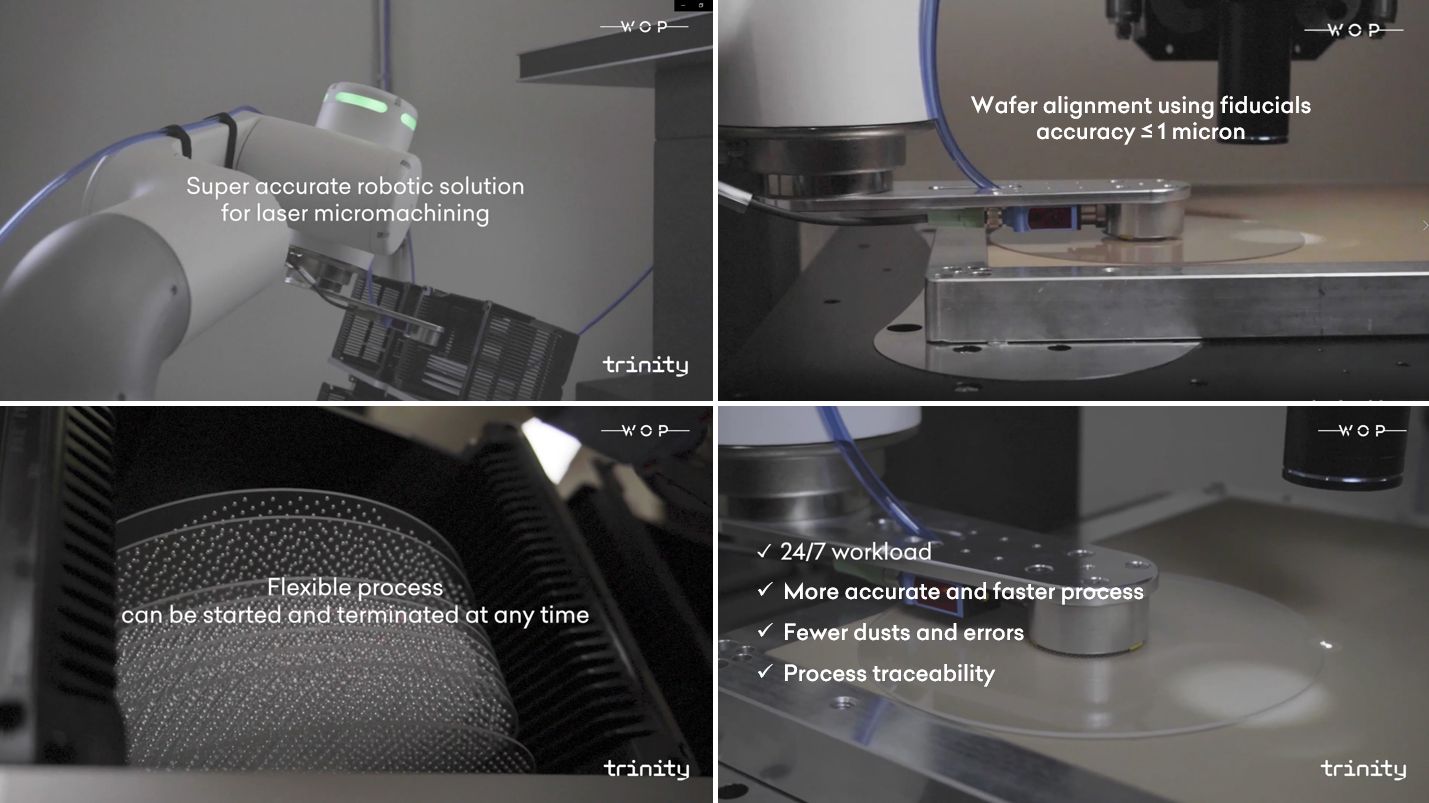

Workshop of Photonics | WOP, in collaboration with ABB AS, under the TRINITY Robotics DIHs project, has developed a complete robotized laser micro-micromachining workstation based on the collaborative robotic solution with the integration of machine vision and custom software.

The main goals behind the project were to develop a robotic solution that would enable us to perform faster, cheaper, and more flexible than conventional laser micromachining solutions.

WHAT ARE THE ACHIEVEMENTS?

PROJECT BACKGROUND

With a strong R&D background, WOP has developed winning laser micromachining solutions over the years. Today, they are already applicable and widely used in industry, leading to a growth in production.

However, manual work – handling of materials – we use today becomes way too time-consuming.

Microfabrication speed and yield is limited to the operator samples handling speed. But, there is an accuracy of 1 µm needed while handling the materials, and there is currently no available robotic solution that can achieve it.

For this purpose, cooperation between two companies has been set up – WOP, operating in laser micromachining, and ABB AS, a robotic solution supplier.

For more information, contact us!The results, achieved using FemtoFBG present the stabilization of blue multi-emitter modules using fiber Bragg…

This EU-funded project is expected to revolutionize Green Energy Generation from photovoltaic panels across Europe.

WOP participates in the BILASURF project – a new European initiative to develop a solution…