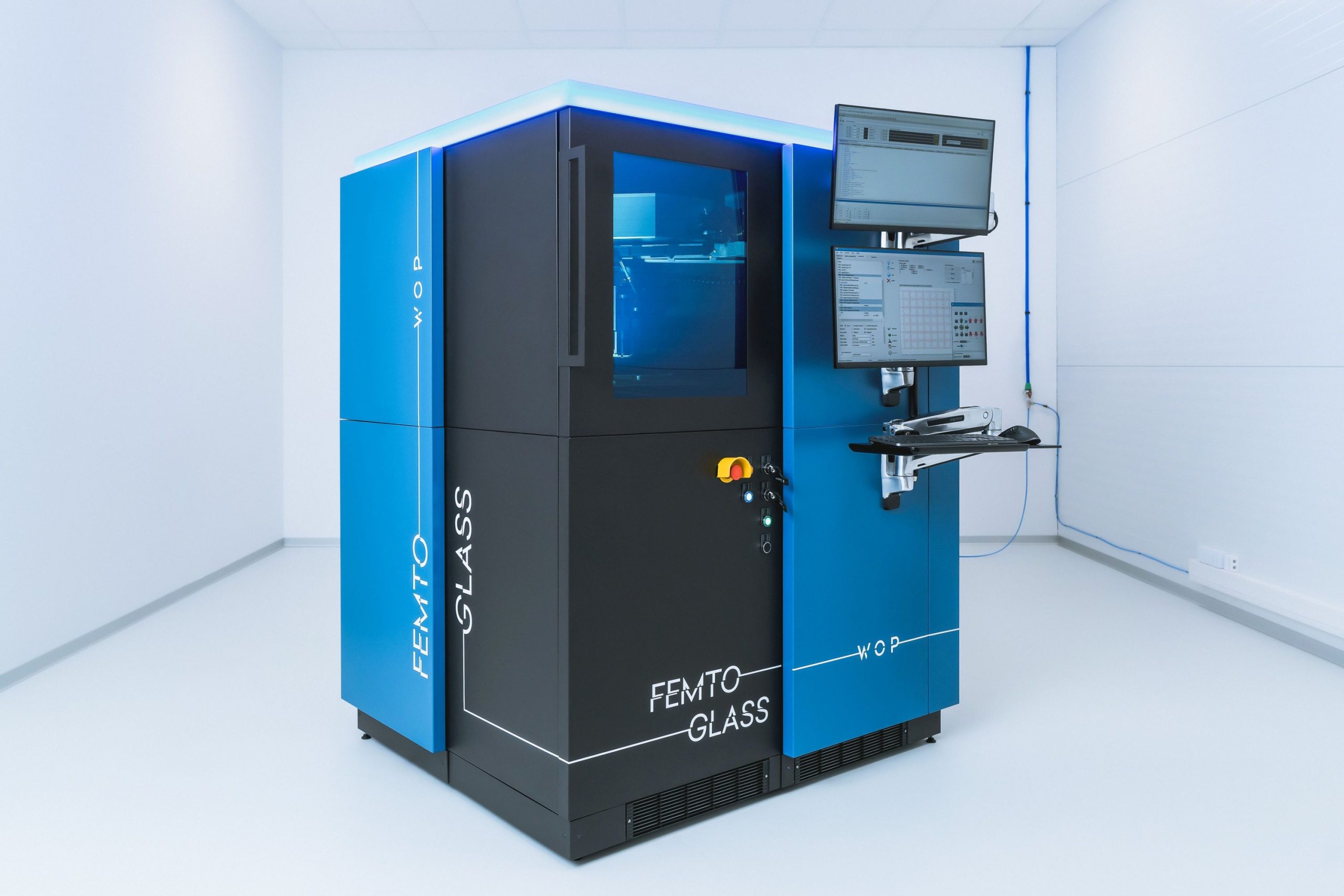

Workshop of Photonics (WOP) introduces FemtoGLASS – a new glass & sapphire laser cutting and dicing system for industry and R&D applications.

The demand for glass as a versatile material in various industries continues to grow, and the need for precision cutting and dicing solutions is constantly increasing.

Addressing this market need, the Workshop of Photonics (WOP) developed a unique state-of-the-art glass and sapphire cutting & dicing technology to overcome today’s market challenges.

It is based on patented WOP glass & sapphire cutting technology, which is unique for ultra-high quality and precision results.

WOP’s patented glass and sapphire cutting technology sets FemtoGLASS apart from alternative solutions in the market.

Its ability to deliver ultra-high quality and precision results makes it a top choice in the semiconductors, microfluidics, and micro-optics industries.

The system overcomes existing market challenges by outperforming other glass-cutting methods in speed, thickness, quality, and possible diversity of materials and shapes.

One of the top highlights of FemtoGLASS is its ability to cut ultra-thin glass up to 2 mm in a single pass. This capability allows for faster processing times and increased productivity.

Integrated beam stabilization and metrology ensure consistent cutting accuracy and reliability, minimizing potential errors and optimizing workflow efficiency.

FemtoGLASS offers flexibility in its dicing process, accommodating different substrate thicknesses. Also, it is designed for all shapes – circular, square, and irregular.

These features ensure optimal results across your applications, making them suitable for various applications, like glass wafer dicing, custom thin glass cutting, mobile phone screens, camera lens cutting, or micro-optic production.

The FemtoGLASS system achieves a cut width of less than 1 μm, ensuring exceptional precision and accuracy. Chipping is minimized to less than 10 μm, significantly reducing the need for post-processing. It not only saves time but also improves overall production efficiency.

FemtoGLASS supports all glass types, including tempered, non-tempered, and sapphire. This versatility enables manufacturers to explore new possibilities and leverage the unique properties of different glass materials.

More about FemtoGLASSThe results, achieved using FemtoFBG present the stabilization of blue multi-emitter modules using fiber Bragg…

This EU-funded project is expected to revolutionize Green Energy Generation from photovoltaic panels across Europe.

WOP participates in the BILASURF project – a new European initiative to develop a solution…