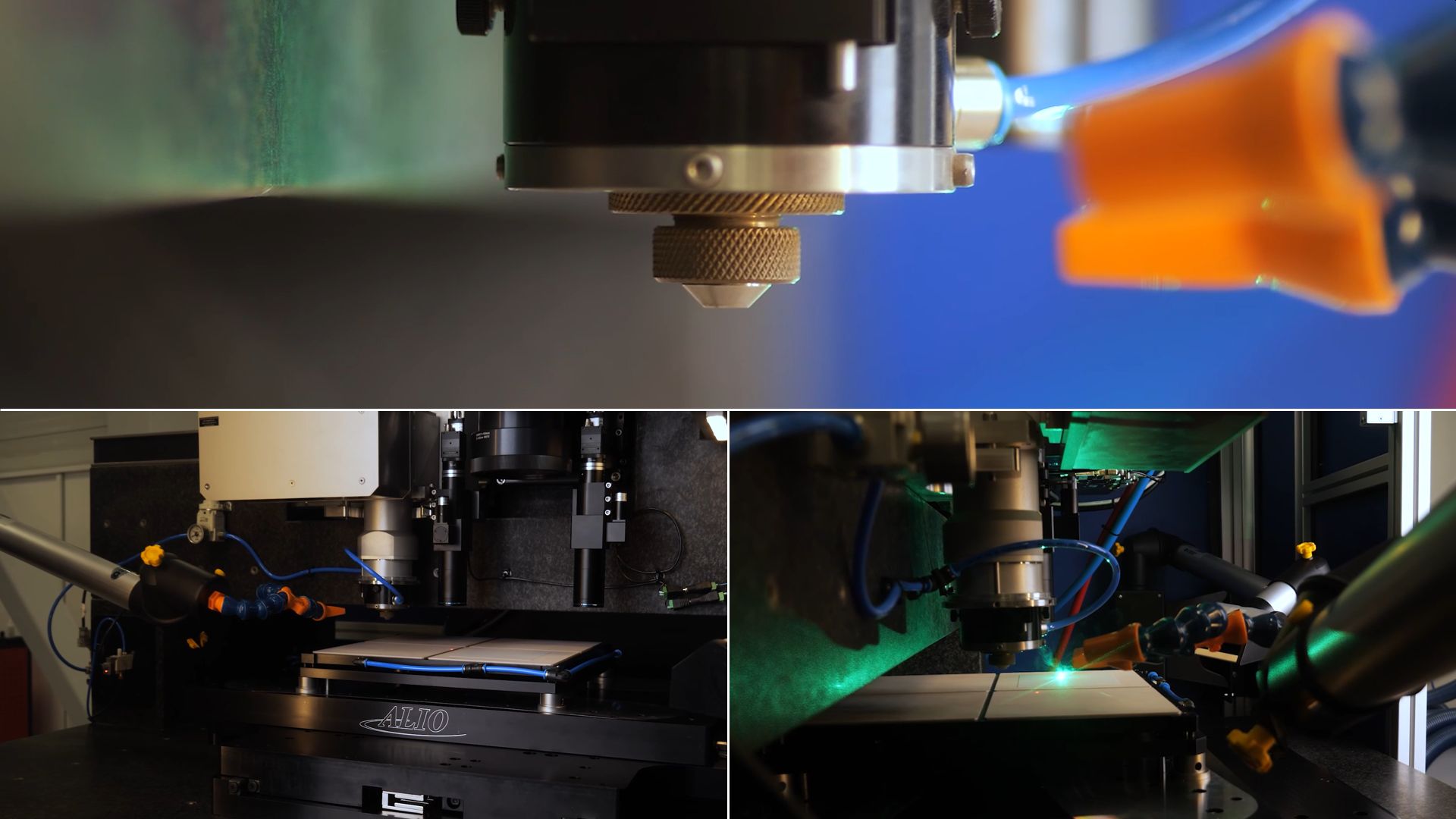

WOP introduces a laser system with an integrated dual-head laser solution for 5-axis drilling and 3-axis patterning, optimized for controlled taper drilling | 5-axis micro processing.

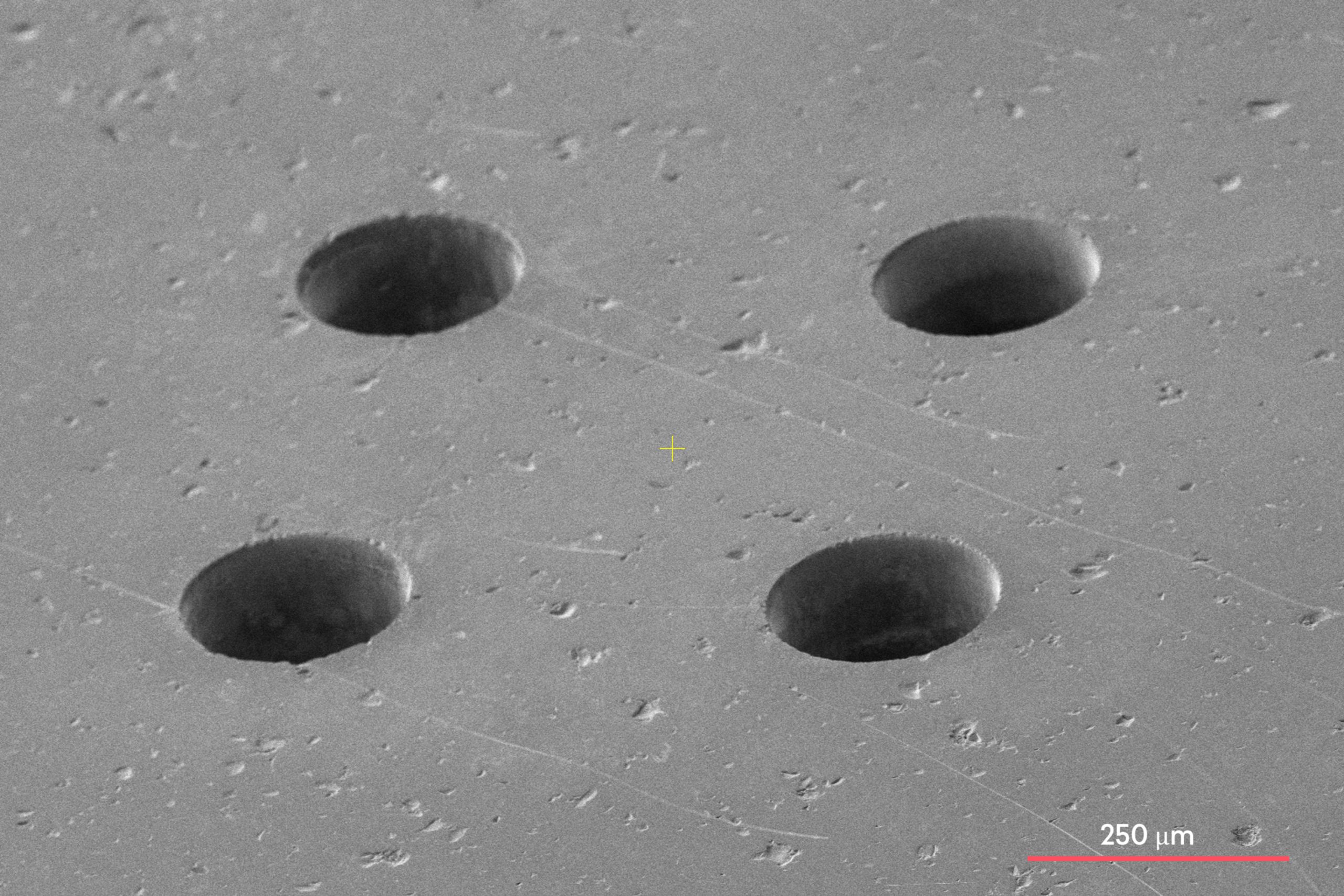

It enables femtosecond laser micromachining of flexibly variable geometries, e.g. fabrication of positively/negatively conical or ideal cylindrical, round, or elliptical drill holes with high aspect ratios.

Preparation of tens, hundreds, or thousands of samples for the drilling and micro-processing process can be a time-consuming and daunting task that takes weeks or even months to achieve the desired quality. It can be frustrating to repeat the preparation process every time the parameters need to be changed until the desired result is achieved.

Our new SCA Precession feature can help by automating repetitive steps, reducing the effort required to achieve the desired drilling and micro-processing results:

To promote the growth of export competitiveness of high-added value products and services.

The results, achieved using FemtoFBG present the stabilization of blue multi-emitter modules using fiber Bragg…

This EU-funded project is expected to revolutionize Green Energy Generation from photovoltaic panels across Europe.